| |

Neoteric Hovercraft Technology Neoteric Hovercraft Technology

Rigorous digitizing/CNC tooling

Perpetuating its legacy of fusing advanced engineering with meticulous hands-on workmanship, Neoteric is moving into the future. In consultation with 3D Engineering Solutions of Cincinnati, Ohio, a noted 3D scanning and metrology firm, the premier hovercraft on the market is sure to maintain its leading edge.

Using the state-of-the-art Faro 3D scanner, every major structural component of the HoverTrek™ has been digitized by 3D Engineering, many of them honed to function and fit better than ever. The HoverTrek’s™ tooling plugs have been scanned, evaluated and skillfully upgraded using NX Solid Modeling software.

As components meet Neoteric’s standards, this data is provided to a select machine shop, where it comes to life on the 5-axis CNC machines of the tool builder. Thousands of passes are made by the CNC cutter head, each accurate to within a few thousandths of an inch.

This painstaking process creates enhanced tooling plugs, from which precise hovercraft tooling molds are constructed. In keeping with Neoteric’s tradition of combining high technology with handcrafted artisanship, the molds are then hand-finished by Neoteric personnel.

This ongoing mold generation process ensures that all Neoteric Hovercraft maintain the highest structure tolerance, fit and finish of any light hovercraft in the world.

In the initial step of the digitizing process, 3D Engineering collects data from the Neoteric 6-passenger hovercraft body plug. The Cincinnati, Ohio firm utilizes a 7-axis Faro Platinum LaserScan CMM, which is capable of collecting 20,000 data points per second with accuracy of 0.005 inch

In the initial step of the digitizing process, 3D Engineering collects data from the Neoteric 6-passenger hovercraft body plug. The Cincinnati, Ohio firm utilizes a 7-axis Faro Platinum LaserScan CMM, which is capable of collecting 20,000 data points per second with accuracy of 0.005 inch |

|

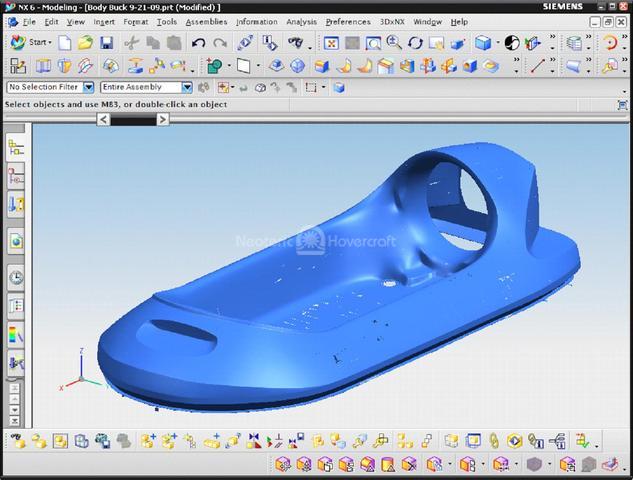

Here, the data points from the 6-passenger HoverTrek™ body plug have been uploaded into NX parametric feature-based modeling software. NX software is widely used in the automotive and aerospace sectors due to its ability to produce high quality models. Here, the data points from the 6-passenger HoverTrek™ body plug have been uploaded into NX parametric feature-based modeling software. NX software is widely used in the automotive and aerospace sectors due to its ability to produce high quality models. |

|

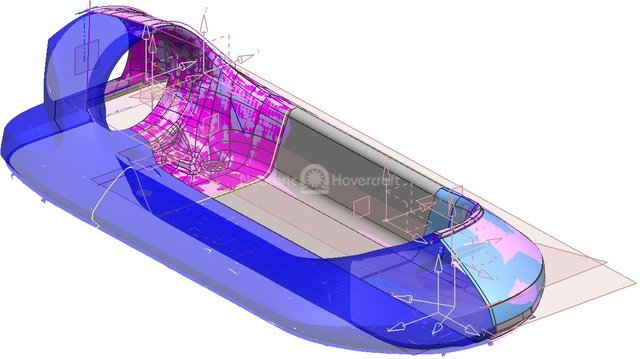

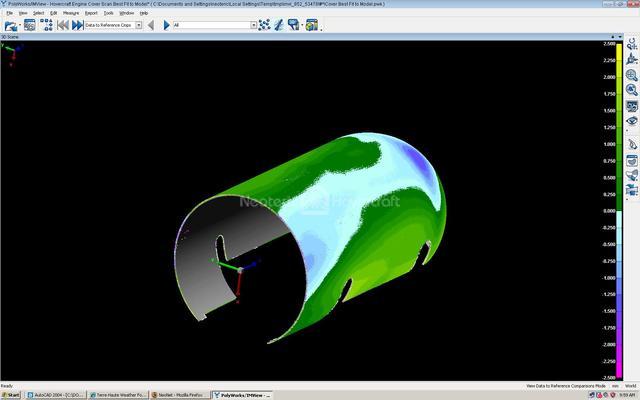

After the data points have been surfaced, 3D Engineering implements any design upgrades, and then refines Neoteric models to meet the company's high precision standards After the data points have been surfaced, 3D Engineering implements any design upgrades, and then refines Neoteric models to meet the company's high precision standards. |

|

The highly refined models created by 3D Engineering are used to create enhanced tooling plugs, which are used to build ultra-precise HoverTrek™ molds. The highly refined models created by 3D Engineering are used to create enhanced tooling plugs, which are used to build ultra-precise HoverTrek™ molds. |

|

The meticulous modeling process gives Neoteric the capability to run design studies and in-depth reviews. This research data undergoes thorough analysis and allows Neoteric to eliminate potential flaws in the HoverTrek™. The meticulous modeling process gives Neoteric the capability to run design studies and in-depth reviews. This research data undergoes thorough analysis and allows Neoteric to eliminate potential flaws in the HoverTrek™. |

|

At the conclusion of the refinement process, the data is forwarded to the Neoteric plug builder, who inputs the date into CNC routers that machine the HoverTrek's™ tooling to within several thousandths of an inch. Other than at Neoteric, tooling this accurate is unseen in the light hovercraft industry. At the conclusion of the refinement process, the data is forwarded to the Neoteric plug builder, who inputs the date into CNC routers that machine the HoverTrek's™ tooling to within several thousandths of an inch. Other than at Neoteric, tooling this accurate is unseen in the light hovercraft industry. |

|

|

|

|